NewTor

Torsional Machines

NewTor

NewTOR systems use Brushless or Torque motors and are designed for the execution of static, semi-static, dynamic and fatigue tests on many types of components and materials.

The RTC 9001 controller and its matching SS9000 software make NewTOR systems ideal for any application.

The direct coupling, without gearboxes (direct drive), avoid the backlash and reduces the inertia of the rotating masses making these systems ideal for high load fatigue tests and high test frequencies.

High stiffness test frame, realized with motor flange and sliding counter-flange on linear guides, ensures maximum versatility and test repeatability.

Reliability, accuracy, “table top” configuration, low consumption and completely oil free.

Utilities

oil free

bassi consumi

elevata flessibilità

table top

facile utilizzo

Applications

NewTOR systems allow to realize different types of configuration thanks to the versatility of the gripping systems (plates or spindles) and the working length realized with the sliding counter-flange.

The performance of motors, the accuracy of used sensors and the simple and intuitive software interface make the NewTOR series products ideal for the following industries:

- Biomedical

- Rubber and Plastics

- Mechanical parts and components

- 3D printed objects

- Torsion springs, wires, fasteners

- Composite meterials

Volta EMT

Electro-mechanical Machines

VOLTA-EMT

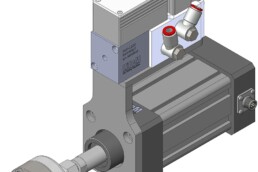

The electromechanical test machine VOLTA-EMT, realized with ball-screw linear actuator, is designed for the execution of static, semi-static, dynamic and fatigue tests on many types of components and materials.

Combined with an RTC 9001 controller and related software, the VOLTA system is the ideal solution for use in a range of fields.

The movable cross strut and the large worktop make it easy to clamp even the most complex samples.

Reliability, accuracy, “table top” configuration, low consumption and completely oil free.

The VOLTA testing systems are ideal for use in any test laboratory.

Utilities

oil free

low consumption

maximum flexibility

table top

easy to use

Applications

VOLTA-EMT electromechanical test systems are used in all fields of application.

The performance of the linear actuator, the accuracy of used sensors and the simple and intuitive software interface make the VOLTA series products ideal for the following industries:

- Biomedical

- Plastics

- Mechanical parts and components

- Rubber

- 3D printed objects

- Fabrics and ropes

- Springs

- Composite meterials

New Vibrodine Vibra-9001

NEW VIBRODYNE VIBRA-9001

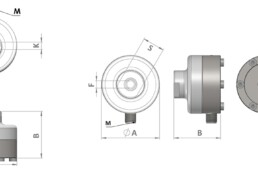

VIBRA-9001 is the first mechanical vibrodyne with linear actuator, designed for applications in civil engineering field, able of generating constant amplitude forcing along with the frequency variation.

VIBRA-9001 was born from the collaboration between EnginLab and DRC and belongs to the family of electrodynamic machines developed and distributed under the LiTeM brand.

The structure of VIBRA-9001 is made entirely of aluminum. This makes it particularly manageable and easy to transport at the structure to be investigated, without the help of machinery lifting and handling equipment, reducing time and installation costs.

The modular masses are set in motion by the linear motor and can be easily placed on the upper tray, allowing the generation of different forcing according to requirements.

Using the RTC 9000-VIBRA Real Time Controller and the SHAKER software tool, it is possible to set the oscillating frequency (in steps or in frequency sweep mode) and the dwell time at desired frequencies.

The VIBRA-9001 linear vibrodyne can control the slide amplitude strokes, thus obtaining constant and appropriate forcing even at low frequencies; which is impossible using normal rotating masses vibrodynes.

Using the Real Time Controller RTC 9000-VIBRA bi-axial (2 indipendent or simultaneous axes) and the SHAKER Software Tool it is possible to control two VIBRODYNES at the same time, by setting the phase between them at will or by making them work independently.

The linear motor is driven by the LiTeM servo-drive EM20 series, included in the kit.

The 4 read-only channels on the Controller allow the acquisition of 4 accelerometers installed on the structure.

VIBRA-9001 is indispensable in all dynamic identification activities with EMA (Experimental Modal Analysis) techniques and in all cases where it is necessary an appropriate and constant forcing even at low excitation frequencies.

Vibrodyne VIBRA-9001

LINEAR VIBRODYNE

VIBRA-9001

VIBRA-9001 is the first mechanical vibrodyne with linear actuator able of generating constant amplitude forcing along with the frequency variation.

The aluminum structure and the optimized design make this vibrodyne particularly manageable and easy to transport. The low weight and the compact footprint allow to easily instal VIBRA-9001 to the structure under investigation; without the help of machinery lifting and handling equipment.

The system is available with different slide lengths depending on the applications.

Utilities

oil free

bassi consumi

low weight and compact footprint

elevata flessibilità

easy to transport

facile utilizzo

Applications

The linear vibrodyne VIBRA-9001 is designed for applications in civil engineering field. It is indispensable in all dynamic identification activities with EMA (Experimental Modal Analysis) techniques and in all cases where it is necessary an appropriate and constant forcing even at low excitation frequencies.

GALLERY

Video Applications

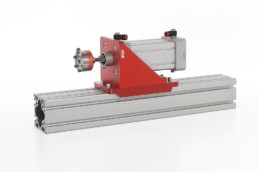

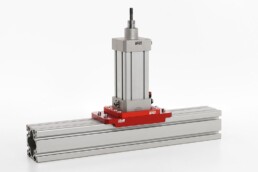

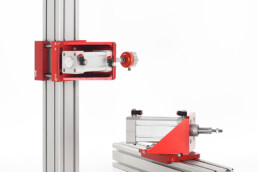

Actuator Kit

Pneumatic testing systems

Actuator Kit

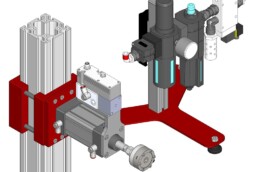

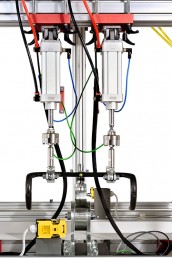

The pneumatic actuator kit includes all the components required to run static, dynamic and fatigue tests.

It is compatible with RTC 9000 Real Time Controllers and it can be used for tests conducted with PN-MF (Pneumatic Modular Frame) systems, which are designed and produced by LiTeM.

The actuator kit can be integrated into test benches made by the end user; in this context, LiTem can provide all the necessary advice for the correct construction and integration of the test benches.

Utilities

oil free

elevata flessibilità

facile utilizzo

customizable

Applications

The actuator kits, combined with the MF-P modular frames or made directly by the end user, are the maximum expression of test flexibility. They allow you to easily create even the most complex set-ups in all application fields.

The simple and intuitive software interface make actuator kits the ideal solution in those sectors that are particularly geared towards know-how processes and technological innovation, Research and Development, Research laboratories at Universities or Research Institutes and Centres:

- Biomedical

- R&D

- Plastics

- Rubber

- 3D Printing (plastics e metals)

- Composit materials

- Springs

- Automotive

- Mechanical components

- Assembled components (even of large dimensions)

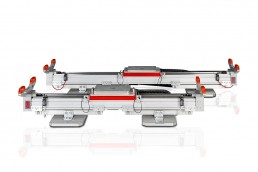

Pneumatic Modular Frame

Pneumatic testing system

Pneumatic modular frame

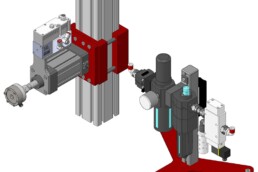

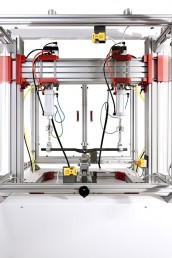

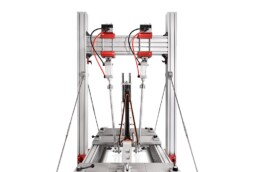

The LiTeM pneumatic test systems include three main components:

• Real Time Controller RTC

• K-PN pneumatic actuator

• MF-P or BYC series modular frame (available in MF-P series, BYC series or custom version)

The range offers single-axis and multi-axis systems. Actuators can have different and interchangeable features; test frames can be configured also according to non-standard shapes and measurements.

Thanks to their flexibility and modularity, these test systems can be easily adapted for any type of need related to the type of test and sample dimensions. The actuator or actuators can be positioned at any point of the frames using the appropriate LiTeM supports.

Utilities

oil free

low consumption

maximum flexibility

table top

easy to use

Applications

Thanks to the modularity several different configurations are possible and this make pneumatic modular frames suitable for all test areas. It is possible to easily switch from table top solutions to more complex test benches specially designed to accommodate even the most bulky samples.

The simple and intuitive software interface make these systems the ideal solution for the following sectors:

- Biomedical

- R&D

- Plastics

- Rubber

- 3D Printing (plastics e metals)

- Composit materials

- Springs

- Mechanical components

- Assembled components (even of large dimensions)

BYC 200 Pneumatic Modular Frame

Pneumatic Modular Frame

BYC 200

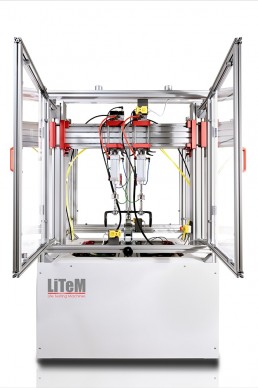

The BYC-200 frame belongs to the family of PN-MF (Pneumatic Modular Frame) systems, designed and produced to run specific tests on components from the bicycle sector.

The system is produced entirely of aluminium and is used to run static and fatigue tests on bicycle handlebar as indicated in the ISO 4210 standard and EN 15194.

The portal structure gives to the bench the necessary stiffness for the correct execution of tests on handlebar and aerodynamic extension according to the standard. The entire test area is protected by polycarbonate panels that allow perfect vision during the tests. The openings interlocking system guarantees a complete operator safety.

The system is compatible with Litem K-PN series pneumatic actuator kits, anchoring brackets and RTC 9000 Real Time Controllers.

Applications

The BYC-100 system is used most commonly and naturally in the bicycle sector. Due to the diversified series of clamps, it is particularly suitable for the following tests:

- Handlebar stem (and assembly) – lateral bending test;

- Handlebar stem – forward bending test;

- Handlebar, stem, bar end, aerodynamic extension – torsional security test;

- Handlebar and stem assembly – fatigue test;

- Handlebar and stem assembly – test method for racing bicycles.

BYC 100 Pneumatic Modular Frame

Pneumatic modular frame

BYC 100

The BYC-100 frame belongs to the family of PN-MF (Pneumatic Modular Frame) systems, designed and produced to run specific tests on components from the bicycle sector.

The system is produced entirely of aluminium and is used to run static and fatigue tests as indicated in the ISO-4210 standard and EN 15194.

The anti-vibration support give the BYC-100 frame the best stability even during the most challenging tests; the portal structure gives to the bench the necessary stiffness for the correct execution of tests on frames and on bicycle components according to the standard. Furthermore, the presence of wheels on the base allows the easy movement of the entire structure within the test laboratory.

The system is compatible with Litem K-PN series pneumatic actuator kits, anchoring brackets and RTC 9000 Real Time Controllers.

Utilities

oil free

low consumption

high flexibility

easy to use

Applications

The BYC-100 system is used most commonly and naturally in the bicycle sector.

Due to the diversified series of clamps, it is particularly suitable for the following tests:

- Fatigue test on the frame with horizontal load

- Fatigue test on the frame with vertical load

- Fatigue test on the frame with the force applied on the pedals - biaxial

- Bi-axial fatigue test on the handlebar

- Fatigue test on the front fork

- Static and fatigue test on the seat

ShoMed 2021

Litem will attend the ShoMed 2021: the fair of products and services for the Medical Devices Industry that will be held on 10 and 11 September in Medolla (MN).

As part of the exposition, important meeting and reference point for this sector, Litem will be present with its own stand and will introduce its innovative test solutions for materials and organic compounds applied to the biomedical sector.

Litem testing machines are able to test heart valves, spinal fixators, stents, hip and prostheses, dental implants… and much more, ensuring compliance of the products and the materials with the standards in the matter of resistance.